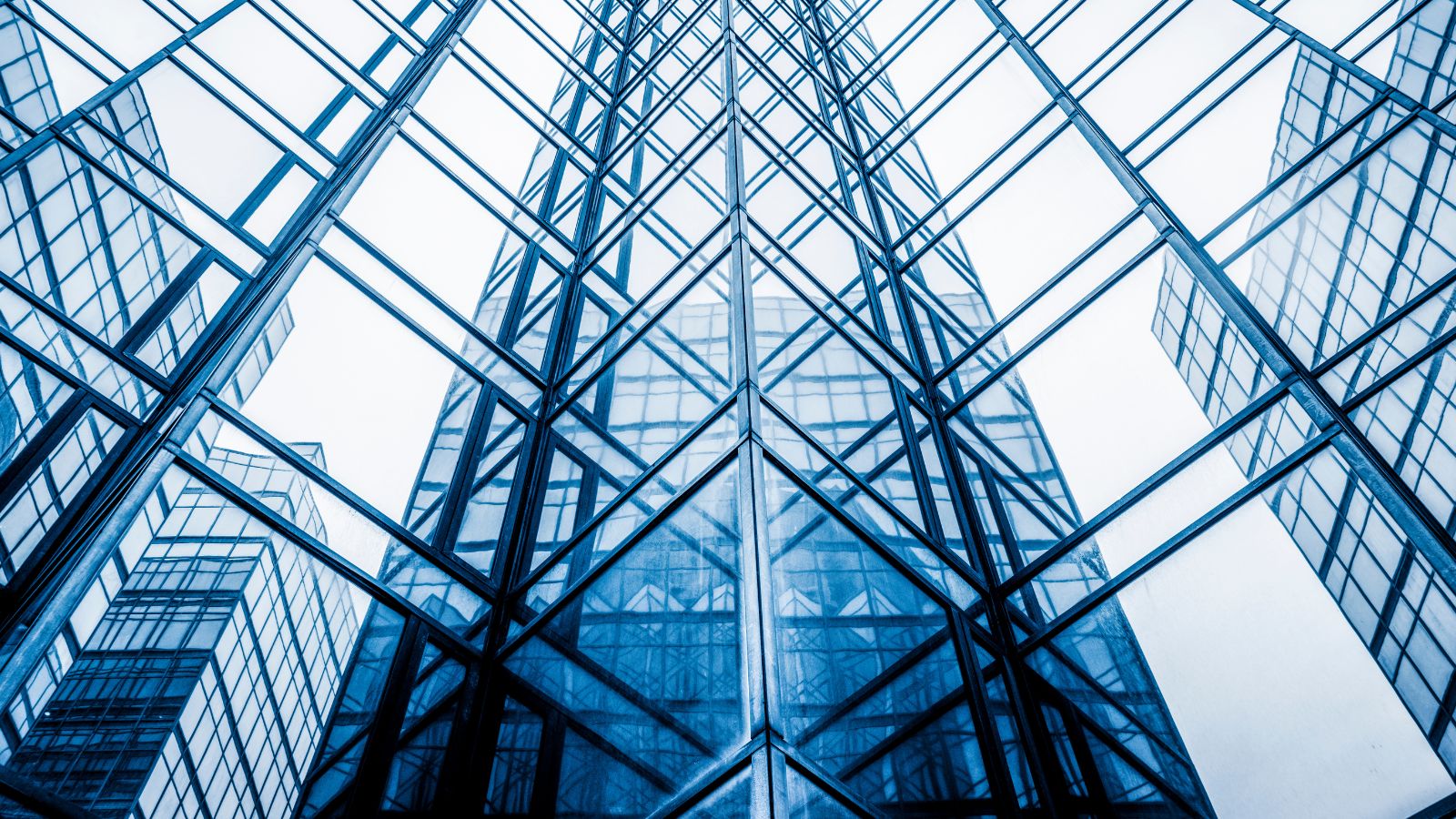

The outer shell of a building functions as its first and foremost barrier to the forces of sky, constantly receiving solar heat, rain, and gentle winds, as well as temperature changes. Apart from structural integrity, the finish applied to building facades, window frames, structures, and railing contributes in the utmost way to the gratifying longevity of the structure. These protective layers stop the offensive elements from deterioration and corrosion and shield the building from degradation so that it looks good for an extended period. Ensuring the application of good-quality finishes that can stand the test of time is the cardinal cardinal of the property upkeep and restoration, ensuring that the external elements can bear any scenario presented by the environment for several decades. Special surface treatments or application processes, with the possible involvement of advanced technology, should be integrated for maximum durability. A good example of such advanced technology is the expert services of industrial powder coaters, whereby professional finishing techniques are used to confer the greatest resistance on metal components.

The Science of Longevity: Materials and Application

Materials used and how they are applied will definitely influence how long the finish will last. Unlike wood, metal, concrete, or composites, each substrate demands a coating uniquely designed to adhere to it and protect it long-term. For example, metallic components such as railings and window frames greatly benefit from finishes that provide maximum corrosion resistance, while wood doors and facades need protection from moisture penetration, UV deterioration, and biological growth. Application methods are equally important, including preparation of the surface, maintaining the correct environmental conditions during application, and adhering strictly to manufacturer recommendations so that the finish performs as intended. The foam gun can also be used in some applications, e.g., sealing joints and applying specialized insulation, to ensure that the foam is applied precisely and thoroughly, which helps increase weather resistance and improve thermal performance of the building envelope.

Varieties of Durable Exterior Finishes

There are several types of durable finishes, each with its own uses and expected outcomes:

Powder Coatings:

Description: A dry powder is applied electrostatically on the metal surface and cured under heat, thus forming a hard finish.

Advantages: Extremely durable-wear resistant against chipping and scratching while providing good protection against corrosion. Available in millions of colors and textures.

Best Use: Window frames, railings, doors, and architectural panels made of metals.

High-Performance Paints and Coatings:

Description: Liquid coatings formulated from modern resins (acrylics, urethanes, fluoropolymers, etc.) made to exhibit best exterior performance.

Advantages: Weather resistive, UV stable, color retention, flexibility, can be applied on different substrates.

Best Use: Facades of buildings (concrete, stucco, masonry), wooden doors, and trims.

Anodizing:

Description: This is an electrochemical treatment for converting a metal surface (usually aluminum) into a hardy, corrosion-resistant anodic oxide finish.

Advantages: Extreemly hard, durable, offers corrosion and abrasion-resistance manteraining a metallic luster.

Best Use: In aluminum window frames, curtain walls, and architectural detailing.

Stains and Sealants (for Wood):

Description: They refer to penetrating or film-forming products that protect wood from moisture, UV rays, and rot.

Advantages: Enhance the natural beauty of wood, good protection, and fairly easy to repapply.

Best Use: Wooden doors, window frames, and timber cladding.

Surface Preparation before Finish Application

No matter what finish is employed, surface preparation is the most important step for longevity. It usually entails-

Cleaning: Completely removing dirt, grime, grease, foreign material.

Rust Removal/Treatment: On metals, this is the removal of all rust and applying rust-inhibiting primer.

Sanding/Profiling: Giving a suitable profile for the coating to bind to.

Priming: Application of a primer that is specifically design for the substrate and topcoat, to aid adhesion and protection.

Skipping of surface preparation spells pre-mature failure of the finish by peeling, bubbling, or blistering, thereby negating the entire investment.

Maintenance and Longevity

Even the toughest finishes warrant maintenance every now and then to maximize longevity. Cleaning and washing every now and then to remove dirt and pollutants, prompt touchups to minor dings and damages, and strict compliance with manufacture recommendations for recoating intervals upon the exterior finishes will considerably prolong its life. By carrying out proactive maintenance instead of delayed rehabilitation, building looks and integrity will be maintained for decades.

Conclusion

Durable finishes are, therefore, considered the first line of defense for exterior building elements against environmental insults ensuring their structural longevity and curb appeal. From powder coatings’ tough protection for metal components to high-performance paints on facades, the correct material along with its application are of utmost importance. Equipped with this knowledge and having made surface preparation paramount as well as instituted an unwavering maintenance schedule, property owners can adequately protect their investments and see their buildings marching for many years still strong and visually striking.