Steam turbines are one of the most important pieces of machinery in any power plant. As such, turbines need to be well-maintained in order to maintain optimum efficiency and performance levels. This article will provide you with a step-by-step guide on how to diagnose and fix turbine problems before they cause irreparable damage that can lead to your turbine getting shut down for repair or replacement.

What is a Steam Turbine?

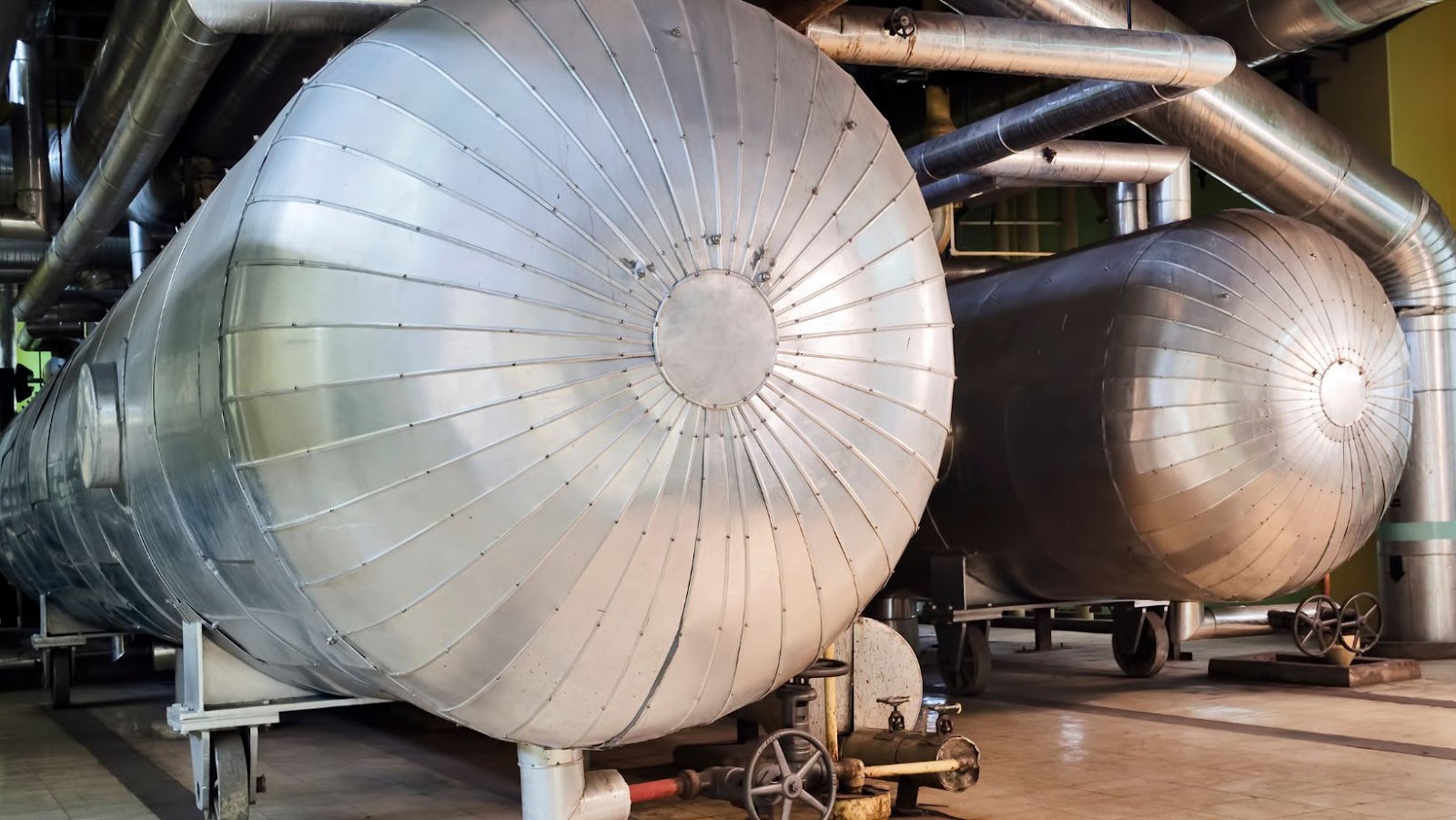

A steam turbine is a mechanical device that converts thermal energy from pressurized steam into rotational energy. Steam turbines are used in a variety of applications, including power generation, ships and locomotives, and industrial process plants.

Steam turbines work by harnessing the energy in steam to drive a rotor. The rotor is connected to a shaft that transmits the rotational energy to a generator, which converts it into electricity.

Pressurized steam is produced by boilers, which use fuel (such as coal, natural gas, or nuclear fuel) to heat water until it reaches its boiling point. The pressurized steam is then fed into the turbine, where it expands and drives the rotor.

The expansion of the steam causes the rotor to rotate at high speeds (up to several thousand revolutions per minute). The rotational energy is transmitted to the generator via the shaft, where it is converted into electricity.

If your steam turbine has broken down, the first step is to call a technician from AlliedPG for repairing steam turbine engine. The technician will assess the situation and determine what needs to be done to fix the steam turbine. In some cases, the turbine can be repaired on-site. In other cases, the turbine may need to be sent to a repair facility. Either way, the technician will have the knowledge and experience to get your turbine up and running again.

What is a Steam Turbine Used For?

A steam turbine is a device that converts the thermal energy of steam into mechanical energy. Steam turbines are used in a variety of settings, including power plants, ships, and locomotives.

While they vary in size and design, all steam turbines work by using the pressure of steam to turn a wheel or turbine. The turbine then turns an electric generator, which produces electricity.

Steam turbines are highly efficient and can operate for long periods of time with little maintenance. However, they can be expensive to repair if they break down.

How Do You Repair a Steam Turbine?

If your steam turbine has broken down, don’t despair! With a little know-how and the right tools, you can repair it yourself in no time. Here’s what you need to do:

First, identify the problem. Is the turbine not spinning? Or are there other issues? Once you know what’s wrong, you can start troubleshooting.

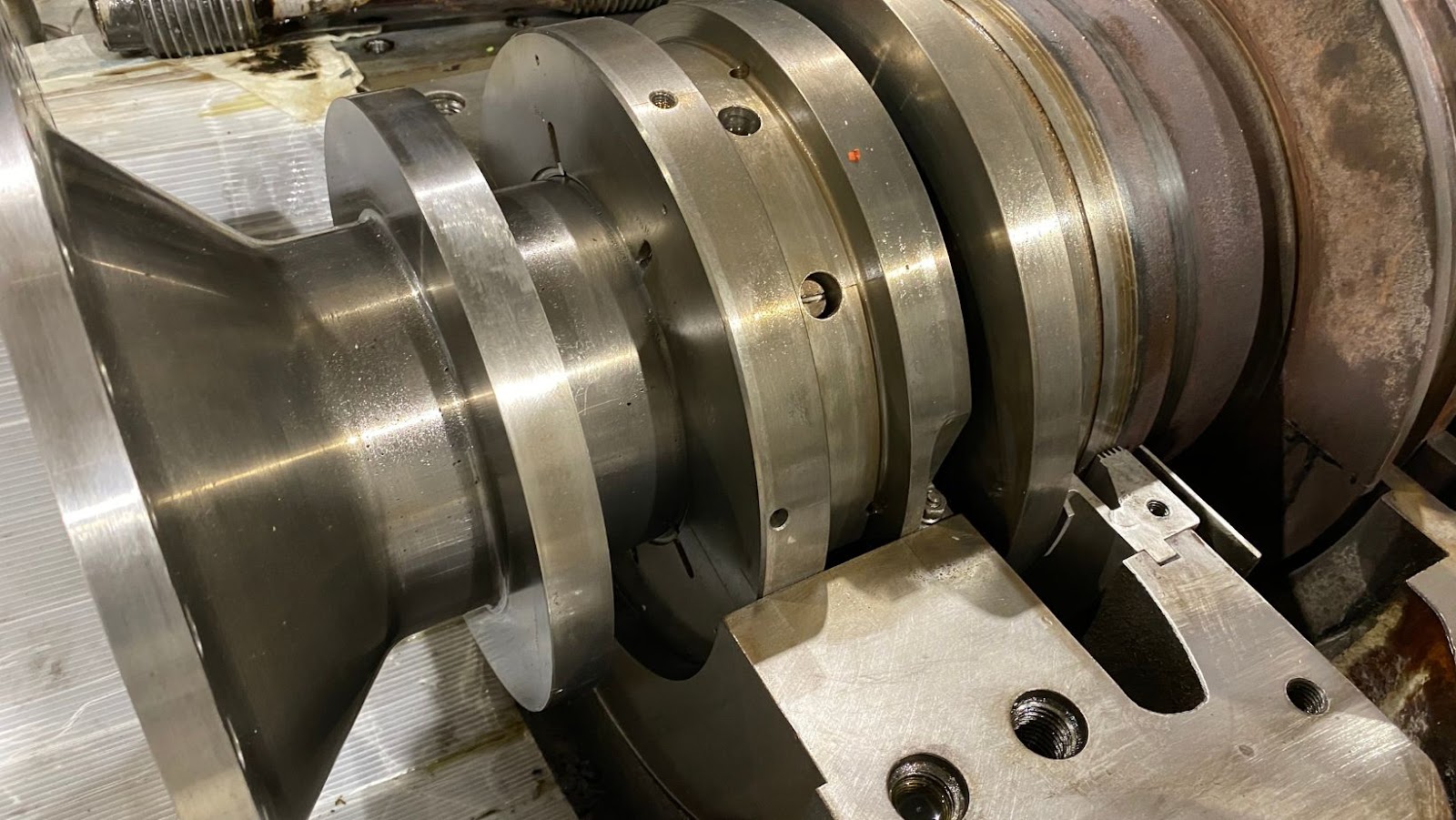

If the turbine isn’t spinning, the first thing to check is the power supply. Make sure that the turbine is properly plugged in and receiving power. If it is, then the next step is to check the bearings. If they’re worn out or damaged, they’ll need to be replaced.

Once you’ve replaced the bearings, spin the turbine by hand to make sure everything is working properly. If it is, then reconnect it to the power supply and turn it on. The turbine should now be up and running again!

Step 1: Remove the Combustion Chamber Valve

- Remove the combustion chamber valve.

- Inspect the valve for any damage or debris.

- If the valve is damaged, replace it with a new one.

- If the valve is not damaged, clean it with a brush and reinstall it.

Step 2: Disconnect and Remove the Flue Gas Condenser Connector

- Disconnect the flue gas condenser connector from the turbine.

- Remove the flue gas condenser connector from the turbine.

- Take out the bolts that hold the flue gas condenser connector in place.

- Lift the flue gas condenser connector off of the turbine.

Step 3: Dismantle the Combustion Chamber Assembly

In order to fix a steam turbine, the first thing you need to do is dismantle the combustion chamber assembly. This can be a tricky process, but it’s important to make sure that you do it correctly in order to avoid any further damage to the turbine. Here are the steps you need to follow:

- First, remove the bolts that hold the combustion chamber in place. Be careful not to lose any of the bolts, as they can be difficult to replace.

- Once the bolts are removed, carefully lift the combustion chamber off of the turbine.

- Inspect the inside of the combustion chamber for any damage or debris. If you see anything that looks out of place, it’s best to consult with a professional before continuing.

- Once you’re satisfied that everything looks good, begin reassembling the combustion chamber by replacing the bolts you removed earlier. Make sure that they’re tightened securely so that there’s no risk of leaks.

- Finally, replace the cover on the combustion chamber and secure it in place.

Step 4: Clean and Check the Flue Gas Condenser

Assuming that you have already completed the first three steps in this guide, it is now time to clean and check the flue gas condenser. This is an important step in the process of fixing a steam turbine, as a clean and well-functioning condenser is necessary for the turbine to operate efficiently.

To clean the condenser, start by removing any debris or build-up that may be present on the inside surfaces. Use a soft brush or cloth to avoid damaging the delicate equipment. Once the interior surfaces are clean, rinse them with fresh water to remove any residual dirt or grime.

Next, inspect the condenser for any signs of damage or wear and tear. If any damage is found, it will need to be repaired or replaced before the turbine can be used again. Once you have confirmed that the condenser is in good working order, reassemble it and reconnect it to the turbine.

Step 5: Cleaning

If your steam turbine is not working properly, it is important to clean it before attempting any repairs. Begin by shutting down the turbine and allowing it to cool. Once it is cool, remove any debris or dirt that may be blocking the blades or other parts of the turbine. You can use a soft brush or cloth to gently remove any build-up.

Next, check the bearings and other moving parts for wear and tear. If any parts are damaged, they will need to be replaced. Once you have inspected all of the parts, you can begin cleaning the turbine.

Start by rinsing off the outside of the turbine with clean water. Then, using a mild soap or detergent, clean all of the areas that you removed debris from earlier. Be sure to rinse away all of the soap before continuing.

Now it is time to clean the inside of the turbine. First, remove any rust that may have built up inside by scrubbing it with a wire brush or sandpaper. Next, use a high-pressure hose to blast away any remaining dirt or debris. Finally, rinse out the interior thoroughly with clean water until no soap residue remains.

By following these simple steps, you can easily clean your steam turbine and get it back up and running smoothly again.